Leading the Competition

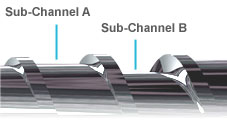

The VBET screw channel is divided into two sub-channels. The particles continuously change their position as they flow from one sub-channel into another sub-channel along the screw. A particle in the surface layer of one sub-channel ends up in the center layer of the other sub-channel. This Solid/Melt Flow mechanism gives uniform melt quality and uniform melt temperature by continuously mixing the melt. Undesirable hot spots inside the screw channel are eliminated.

Conduction is the key to the BARR VBET.

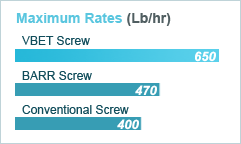

The VBET's new low-shear design uses almost half of its length as an Energy Trasfer section, which provides an increase in conductive melting by almost 30%. The VBET Energy Transfer section melts 30-50% of the polymer, eliminating the need for downstream cooling. This not only reduces heat loss, but also, allows a much lower melt temperature. Lower melt temperatures, in turn, mean the processor can facilitate higher maximum rates.

The VBET Difference

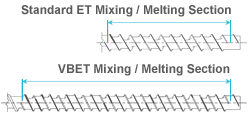

Not only has the VBET improved upon the strength of the BARR ET Screw, it incorporates more of the processing power. The Mixing/Melting Section fo the VBET Screw is 30% to 50% longer than the ET Screw.

Typical Barrier Screw |

VBET Screw |

Largely keeps

unmelted and melted resin separated

90% of polymer

melted through

shearing

Melt film thickness

in barrier section is

very small

Requires downstream

cooling due to high

temperatures

Both pellets and melt

cross between

channels to increase

conductive melting

30 - 50% of polymer

melted through

conduction

Hot melt flows from

one sub-channel into

another

Conductive heat

transfer elminates

need for downstream

cooling