Smart.

The Fluxion Mixer is the smart choice of processors in today’s economy because it meets the cost reduction demands from global competition and because it provides the ability to perform low shear, high intensity mixing of polymer blends and of multiple polymers in recycling.

Economic & Efficient.

The Fluxion Mixer allows processors to color polymers in-house by blending natural resin with color concentrates at the machine or injection lines, thus allowing processors to reduce costs, implement new colors quickly and better control a wide ranges of colors.

Versatile.

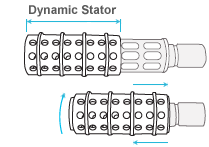

When used for injection molding, the Fluxion Mixer’s design can incorporate a non-return valve. This eliminates the valve as a separate component and increases the available mixer length, a significant advantage since many injection machines offer limited screw length.

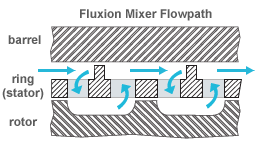

Flow Path

A row of radial rings divides the Fluxion Mixer sleeve into sections. Each section has a series of perpendicular holes that extend through the sleeve base, as shown below. The radial rings prevent material from flowing directly into an adjacent section. As material enters the first section, it is forces through the series of holes in the sleeve towards the rotor. The rotor outer diameter has corresponding grooves or slots that transfer the material under the ring and into the next section of the sleeve. This flow pattern is repeated a number of times until the material exits the mixer.